What can Disc Springs do for you?

Disc springs are used in various applications where high force and limited space are key factors. They are conically formed and its unique shape makes them valuable solution for various engineering challenges.

A very versatile and effective spring, they can be used singularly or multiple discs in a stack, either in series or parallel. They can be configured to provide a solution to many cyclic or static loads.

Also known as Belleville washers or conical washers, disc springs are widely used in industries such as automotive, aerospace, oil and gas, and manufacturing.

Pinstructure offer DIN2093 Disc Springs from stock.

The advantages of disc springs

- Vibration Control

- Thermal Expansion Compensation

- Counteract Relaxation and Bolt Creep

- Energy Storage

- Prevent excessive load

- Valve actuation

Typical industry applications

- Heavy duty bolting

- Electrical connections

- Structural members

- Farm equipment

- Off road equipment

- Vibratory equipment

- Pipe supports

- Equipment mounts

- High temperature pipe flanges

Disc Springs in the Energy sector

- Steam Turbines

- Solar Panels

- Wind Turbines

- Oil and Gas

Disc Springs are commonly used in the energy sector, in the assembly of solar panels and wind turbines and because of their robust nature, are also used in the oil and gas sector.

Disc springs are used in steam turbine systems to maintain the alignment and balance of rotating parts. They are ideal for installation in rotating applications because of their symmetrical shape. They are also used in valve assemblies to ensure proper sealing and pressure control.

Renewable Energy Sector

Renewable energy systems, such as wind turbines and solar panels, require components that can withstand extreme environmental conditions. Disc springs are used in wind turbine systems, providing damping and load distribution. Using disc springs over traditional springs makes automatic assembly lines easier as disc springs will not get tangled, vastly reducing issues in the manufacturing process of solar panels and wind turbines. They are also utilized in solar panel tracking systems, assisting in maintaining optimal positioning.

With the demand for solar panels expected to increase by almost 10% by 2030 and the growing popularity of wind farms, an exponential growth in the manufacturing capacity of both solar panels and wind turbines is required and with the use of components such as disc springs increasing manufacturing efficiency, this can only bring us all closer to our global net-zero goals.

Oil and Gas sector

As previously mentioned, disc springs can also withstand extreme environmental conditions and their ability of disc springs to withstand high pressures and high temperatures allows its use in harsh environments like in the Oil and Gas industry. Disc Springs are used in valves and wellhead equipment as they allow pressure control and to maintain proper sealing.

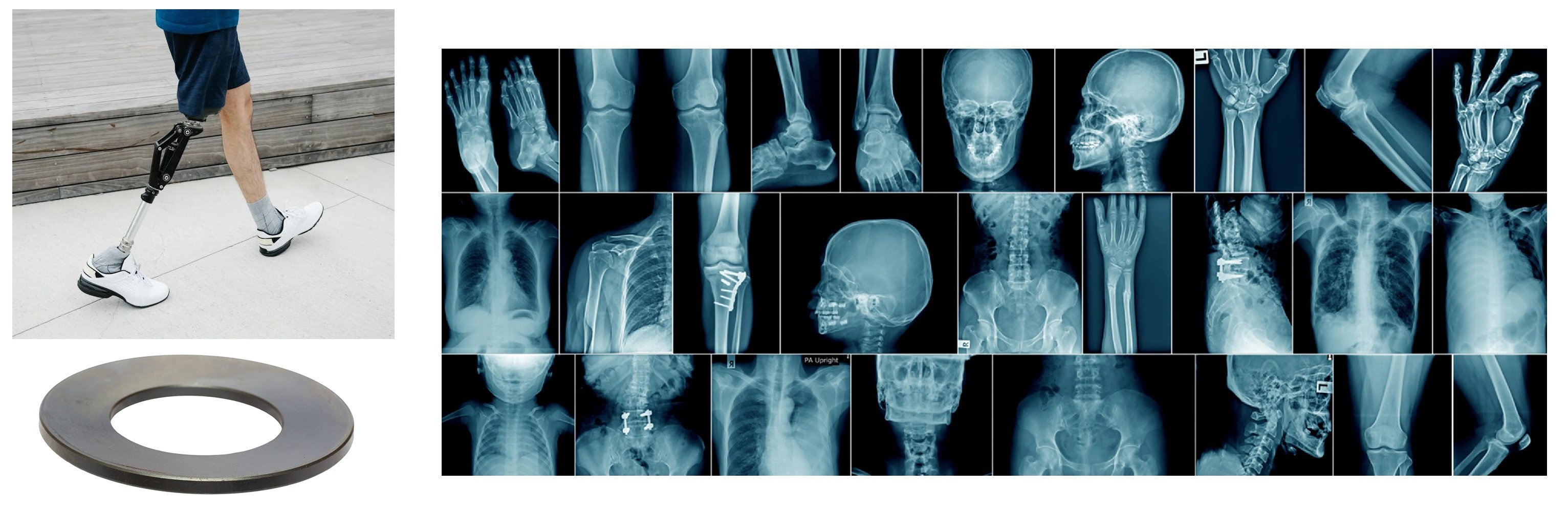

Disc Springs in the Medical Sector

- Surgical Instruments

- X-Ray Machines

- Prosthetics

The advantages of using disc springs make these ideal for the assembly of various types of medical devices and equipment. Disc springs are widely used for vibration control and are helpful in keeping bolted connections secure in transportable hospital equipment like X-ray machines.

The conical shape of disc springs and its material allow for disc springs to be both robust and flexible. This makes its use ideal in the assembly of prosthetics as they provide both flexibility and robustness where necessary. Disc springs are used in the assembly of surgical instruments to provide tension control.

Disc Springs in the Aerospace, Military and Automotive sectors

- Aircraft shock absorption

- Tanks

- Armoured vehicles

- Firearms

- Braking systems

- Shock absorbers

- Clutches

Aerospace sector

In the aerospace sector, lightweight and heavy-duty components are a must. The high load/space ratio of disc springs makes its use in aerospace crucial. Discs springs are used in landing gear systems for shock absorption during takeoff and landing. As disc springs can withstand extreme temperature and vibrations, they are also used in aerospace engines to maintain the integrity of critical components.

Defense and Military sector

Disc springs are used to provide support and cushioning, and are used in the assembly of tanks, armored vehicles and in aircrafts, as mentioned above. They are also used in firearms to help absorb recoil.

Automotive sector

Disc springs have various applications in the automotive industry and are heavily utilized in suspension systems, clutches, transmissions, and engine components. The ability of disc springs to store energy and release energy when required, make them ideal for use in the assembly of shock absorbers and clutches. They also provide stability specifically in suspension systems which result in reduced excessive movement. Disc springs help maintain proper tension and load distribution and prevent damage to components due to excessive torque or loads.

Disc Springs in the Engineering sector

- Button mechanisms in electronics

- Suspension systems

- Clutches and braking systems

- Presses, punches and stamping machines

- Machinery

- Structures

Electronics Sector

Disc Springs are used in electronics, particularly in connectors and switches. Disc springs ensure secure connections in electronics as a reliable contact force. They are also used in button mechanisms, providing reliable button feedback in electronic mobile devices.

Mechanical Engineering Sector

In the mechanical engineering sector, Disc springs have extensive use in different applications, such as in suspension, clutch and braking systems. Disc springs are used in suspension systems as a compact but reliable solution for absorbing shocks and vibrations. They are also used to transmit torque and maintain proper tension in clutches and braking systems.

Industrial Machinery Sector

Disc springs are widely used in industrial machinery for their durability and ability to withstand heavy loads. Disc springs are used in the assembly of machinery to help absorb operational force, like presses, punches, and stamping machines. They are also widely used in machinery and to build structures, for their ability to control vibrations and reduce unwanted oscillations. In conveyor systems, disc springs also provide tension and alignment control.